The proliferation of electronic componentry into virtually all walks of life means that connectors and other components must be integrated into a wide variety of application areas and specifications. Many people, fundamentally, expect that electronic devices will be anywhere at any time, regardless of how rugged the environment is or whether there are safety considerations that might have recently constrained what is possible in the design space.

For example, high voltages are needed in various harsh environment applications, including high-voltage test equipment, construction, hybrid and electric vehicles, and outdoor events with high electrical output (such as concerts or sporting events). However, what constitutes high voltage is highly dependent on the industry involved and the application.

Safety Concerns with High-Voltage Connectors

Choosing the right high-voltage connector for an application can be extremely challenging, in part because these connectors must meet particular safety requirements. This alone makes it very important to know the relevant rules, regulations, and standards related to a product. Testing may also be required before a product is released. Outside of compliance with safety regulations, equipment and personnel must be protected from the dangers of working with high-voltage connectors.

Specifying High-Voltage Connectors

While there are always considerations that must be accounted for when specifying an electrical connector, there are additional factors to consider when selecting high-voltage connectors. As with any other connector, attention must be given to the durability and material composition to ensure it is well-suited for the specific operating environment. Additionally, connectors should be chosen to prevent fires and electrical shock.

Minimizing the risk of corona and arcing is also an essential part of choosing a high-voltage connector. A corona discharge is a type of electrical discharge caused by ionization of the air surrounding a conductor carrying a high voltage. A corona discharge will occur when the strength (potential gradient) of the electric field around the conductor goes beyond the dielectric strength of air. When this happens, a conductive region is formed in the air. The voltage required for corona to occur is known as the inception voltage.

A corona discharge is an unwanted side effect for many high-voltage applications because it can result in thermal breakdown, possible EM/RF (electromagnetic/radio frequency) interference, and power loss. Even though it is considered a low-energy process, it can cause insulators to break down and systems to fail if it occurs over significant periods of time. In high-voltage power transmission lines, for example, corona falls under the category of an economic waste of energy utilities. A further danger related to corona is its ability to initiate electrical arcing which can, in turn, create dangerous fires.

Minimizing the Risk of Corona and Arcing

Three specific engineering considerations must be accounted for early in the design process to minimize the effects of corona and arcing: atmospheric conditions, spacing, and choice of materials.

Atmospheric Conditions

Atmospheric conditions of the operating environment include temperature, pressure, humidity, and particulates. For example, lower pressures combined with higher temperatures can produce corona at lower voltages. Large temperature changes can result in contaminated condensation which, if it makes its way into the connector, reduces the required voltage for corona discharge to occur.

Material and Design Choice

The choice of materials and design of the connector is vital in choosing the right high voltage connector. Designs with sharp points or edges should be avoided because they will reduce the inception voltage for corona; instead, it is best to use rounded, smooth surfaces. In addition, non-porous insulators are better at preventing breakdown but may not always be practical inside a small space like a connector. On the other hand, insulating materials such as PEEK, Teflon (PTFE), and silicone rubber are well adapted to connector design because they maximize creepage distance and air clearance and can handle harsh environments.

Connector Spacing

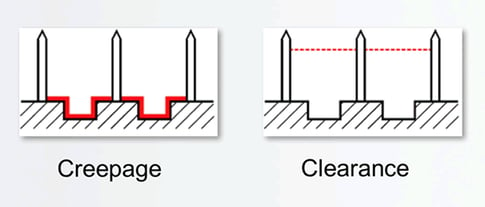

Spacing is another key issue for design engineers when high-voltage connectors are involved because it becomes necessary to maximize the distance between conductors that have large voltage differentials. This is necessary because the distance between conductors significantly affects the inception voltage for corona to occur. Correct spacing (also referred to as clearance and creepage) ensures a proper safety margin and reduces the risk of failure.

Figure 1: Creepage vs. clearance. (Source: Connector Supplier)

Figure 1: Creepage vs. clearance. (Source: Connector Supplier)

PEI-Genesis: Your Partner for High-Voltage Connectors

It is critical to understand the key considerations involved in specifying the correct high-voltage connectors that will deliver reliability, long-term performance, and safety. At PEI-Genesis, our team of connector experts can help you navigate the design choices involved with choosing the right high-voltage connector for your applications.